Process & Quality

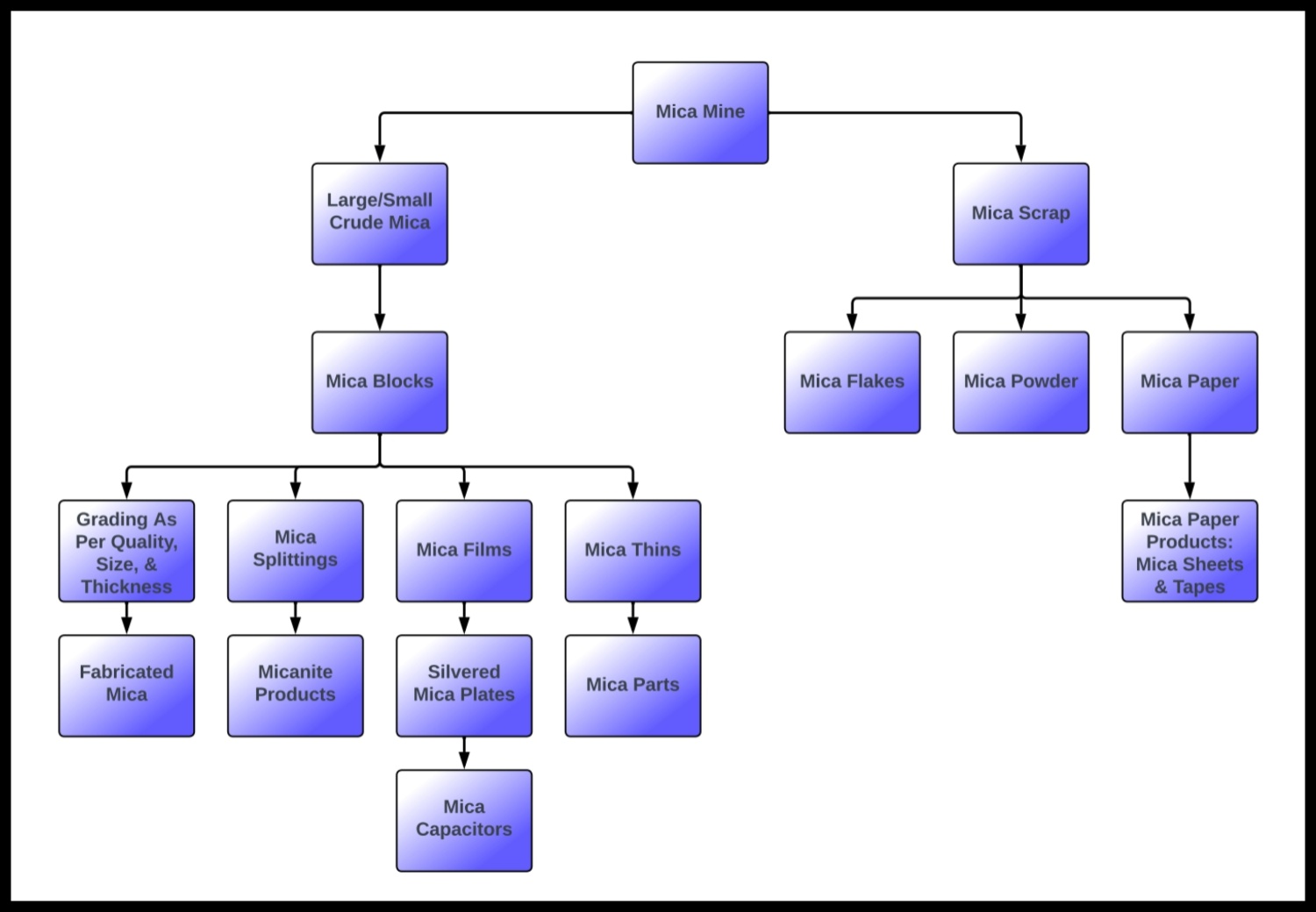

Process Flowchart

Quality

Documentation has been made for the purpose of classification of Mica according to diverse sizes and qualities. The typical pattern of grading laid down by ASTM, BSI, DIN, ISI, and NEMA standards are followed in order that they may be accepted universally.

The quality determination of Sheet Mica is a matter of visual assessment and judgement. In this system of quality evaluation, emphasis is put on clarity, colour, flatness, hardness, freedom from spots, stains, air bubbles, visible inclusions, and structural imperfections. The grading of size is done based on maximum usable rectangle area that a piece of Sheet Mica may yield.

The quality determination of Ground Mica or Scrap Mica is designed to estimate the degree and level of purity, whiteness, brightness, loss on ignition value, calcination capability, aspect ratio, bulk density, and other facets of the specimen. The grading of particle size is set in terms of millimeters, inches, microns, and mesh counts.

Quality of Mica is a function of many variables. Mutual understanding between the buyer and seller is practiced for individual requirements.