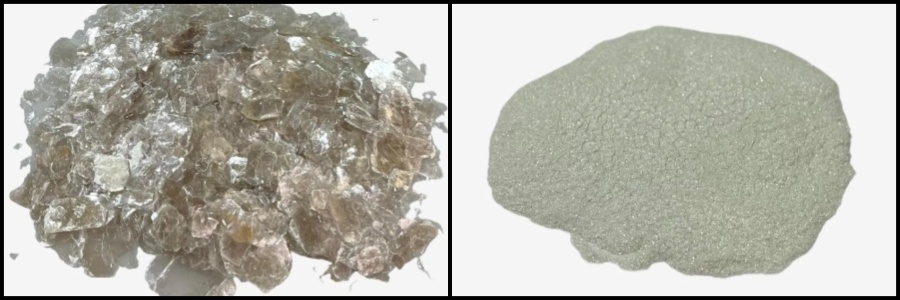

The largest use of Mica, both application-wise and quantitatively, is in the form of Ground Mica. It is prepared from the breaking and grinding of Mica Scrap or waste by a dry ground process. Production is carried out in high-speed rotary hammer mills or pulverizers to generate Mica Flakes and Mica Powder of different particle sizes. Meticulous care and precaution is taken to avoid deterioration of its natural brilliance, colour, and properties. By virtue of its exceptional values and outstanding characteristics, Ground Mica has shown phenomenal growth rendering extensive usage in many industries.

Application:

1. Mica Flakes:

White Mica Flakes of high quality are used for artificial and bright snow impressions. In addition to being beautiful, Mica is chemically inert, fireproof, non-toxic, tough, transparent, and water resistant. As a decorative material to produce glittering effects, it is used by artists, candle makers, Christmas tree creators, crafters, floral designers, scrap bookers, wedding designers, and many more. It is also used to adorn and prettify fancy papers, greeting cards, wall papers, and various novelties.

Mica Flakes are effectively used in water-based oil well drilling operations as a mud additive chemical to prevent loss of circulation and seepage in loose formations. Mica is specially added to overcome the lost circulation zones. The platy structure of it facilitates the overlapping of particles to form a tight layer or wall and acts as a sealant that bridges the openings. Mica-mixed drilling mud helps to seal porous sections of the drill hole and contributes to regain circulation in keeping the solids in suspension. Normally, three grades of Mica Flakes are used for specific purposes: Coarse, Medium, and Fine.

Mica Flakes are indispensably used in the manufacture of pearlescent pigments (pearl luster pigments), which consist of Natural Mica Flakes coated with iron oxide and/or titanium dioxide. They possess a high reflective and refractive index that impart a natural pearl-like luster with abundant fascinating colours and enticing appearances. The unique features make it distinctive and promising in the present age. Pearlescent pigments are applied to numerous industries such as paint, plastic, ceramic, coating, cosmetic, dyeing, leather, paper, printing ink, and rubber.

Substantial quantities of Mica Flakes are processed for producing Wet Ground Mica Powder. The Mica is milled with technique to preserve the sheen and structure of the Mica platelets without altering their natural properties. The Wet Ground Mica Powder product is characterized by brilliant whiteness, good purity, high quality, large diameter-thickness ratio, regular shape, and a smooth surface. Additionally, the product is resistant to chemicals, electricity, and heat. Wet Ground Mica Powder is widely used in fields such as paint, pearlescent pigment, plastic, coating, cosmetic, lubricant, rubber, etc. Compared to other materials, it emerges as an excellent performer.

2. Mica Powder:

Mica Powder is extensively used as a filler in acoustic compounds in the manufacture of automotive components for controlling noise and insulating the heat generated by commercial vehicles for the comfort and well-being of the driver and passengers. The advantages of the anti-vibration, heat protection, and sound damping capabilities of Mica cannot be neglected. Besides, the addition of Mica to acoustic products significantly improves their properties by increasing dimensional stability, stiffness, and strength. It also reduces flammability and warping.

A large tonnage of Mica Powder is used as an inert filler to asphalt and bituminous compositions. Applied as a surface coating to rolled asphalt roofing felt, damp courses, and shingles, Mica increases the hardness of and resistance to mechanical stress and weathering. It prevents the sticking of adjacent surfaces during manufacture and storage. The coating is not absorbed by freshly manufactured roofing because of Mica’s platy structure. It enhances the durability of the roofing product and imparts a glistening appearance. As compared to other materials, the viability of Mica is proven for the above purpose.

The most widespread application of Mica Powder is in automobiles. Mica is used as a reinforcing material in lightweight plastic automobile parts such as car seat backs, fascia and fenders, ignition systems, and panels. Mica-reinforced plastic imparts improved mechanical capabilities together with increased rigidity, stiffness, and strength. It also provides high heat dimensional stability, reduced warping, temperature resistance, and the best surface properties of any filled plastic composite.

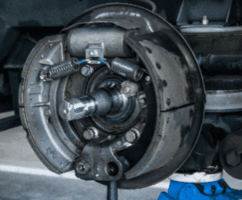

Mica Powder is used as a friction material for asbestos-free brake lining, brake discs, brake pads, brake shoes, clutch facings, etc. Owing to the high thermal resistance of Mica, it reduces the flow of heat and helps keep the brake drums cool. Mica particles are stronger than iron which serves to solidify the product by minimizing warping and preventing microscopic ruptures. Due to the platy structure of Mica, it tends to lock together under compression during processing to form an effective and superior surface. The benefits of Mica are also recognized in curbing noise and providing active environmental protection.

Mica Powder is essentially added and used in the formulation to keep the powder inside the dry fire extinguishers free flowing. Mica is fire resistant and retains the powder mixture from packing tightly in the canister.

Mica Powder is used as a facing agent to improve the surface of the finish casting and prevent defects. It allows gas to escape, enabling the metal to completely fill the mould before hardening. Mica is added to the coating applied to the foundry cores and moulds to avert sand burn in the metal casting and moulding. It safeguards sand from direct contact with the molten metal so that it can be reused for fresh moulds. Mica is also used as an annealing agent for metal treatment because of its high insulation properties.

Significant volumes of Mica Powder are used as fillers in lightweight and prefabricated gypsum panels, slabs, and wall boards for building construction. Mica is chemically inert, fire resistant, free flowing, light in weight, and non-abrasive. Dimensional stability, extremely low water absorption, good insulation and thermal properties, and sound suppression are some of its additional outstanding features. All these desirable characteristics make Mica a justified filler in the plasterboard industry.

Mica Powder is an important constituent as an extender and filler for paint manufacturing. The platy structure of Mica reinforces a protective coating in paints. Its addition augments performance, brightens the tone of coloured pigments, facilitates suspension, increases resistance of paint film to atmospheric weathering and moisture penetration, prevents shearing and shrinking of paint film, and reduces cracking and peeling. Utilization of Mica in paints is universally well established for its functional properties.

Mica Powder can be successfully mixed with various thermoplastic polymeric materials (ABS, BDS, HIPS, PE, PP, PS, etc.) and thermosetting resins (acrylic, polyester, polyurethane, etc.) for use in products having direct contact with food. Mica Powder of different grain sizes can be dispersed and distributed in a single or twin screw extruder, or added directly to the polymer mass by an additional dispenser located at the form. Mica-reinforced plastic boosts material stiffness and strength, and increases adhesion to the substrate. It reduces thermal conductivity, thermal expansion, and wrinkling of the material, and upgrades insulation properties and vibration damping. It is largely used for non-asbestos fillers that improve the physical capabilities of the Mica-plastic composite and provide toughness. The addition of Mica results in better chemical resistance, better dielectric and surface properties, greater flexural modulus and strength, higher heat distortion temperature, and reduced permeability and shrinkage in plastic composites. It is particularly applied in the manufacture of elastomers plastic compounds, thermoplastic polymers, and thermosets, and imparts a gloss of polymer masses.

Mica Powder is used in the manufacture of insulating blocks, bricks, slabs, and tiles because of its excellent insulating and thermal properties. Since Mica bricks can safely withstand extreme temperatures of 1000°C, they enhance furnace efficiency, improve furnace room condition, keep heat losses to a minimum, minimize energy consumption, and reduce operating costs. An additional advantage of Mica bricks is stability after long use.

Mica Powder is a highly useful component as an anti-blocking and anti-sticking compound in the production of rubber tyres for automobiles, airplanes, and motorbikes. Applied as a dusting and releasing agent, it prevents the casings and inner rubber of tyres from sticking to the mould during vulcanization. Mica prevents the movement of Sulphur while permitting air and moisture to escape during curing and creating a uniform structure. As a rubber additive and filler, it improves the hardness, resilience, tear resistance, and tensile strength of rubber articles.

Mica Powder is a cost effective extender and filler in wall board joint cement compounds. It is used to fill and finish the blemishes, joints, and seams on gypsum wall board, between adjacent sheets and other structural constructions. Mica acts as a reinforcing agent for improving the workability of compounds by eliminating peeling, preventing cracking, and reducing shrinkage. The wall surface is protected from moisture absorption since Mica particles are insoluble and impenetrable by water. It also provides a decorative texture and smooth edge to the wall surface.

Mica Powder is well recognized for its use in the manufacture of welding electrodes as a flux coating on the metal wire. Mica is added to the flux with which welding electrodes as coated as arc stabilizers, binders, extrusion agents, fluxing agents, pigments, slag modifiers, and weld pool protectors. Potassium also facilitates reignition of welding rods after interruptions to the current. The Mica coating provides two distinct types of protection. Firstly, it serves in forming a fusible slag and a good seal at the fusion zone of the arc. Secondly, it resists the action of gaseous, heat, and other surrounding atmospheric oxidation. In fact, it is the nature of the Mica coating that largely determines the quality of welding electrodes.