Fabricated Mica applies to the cutting, punching, and stamping of natural sheet Mica to specific shapes, sizes, and thicknesses (within close dimensional tolerances) for electrical and electronic applications. Most Fabricated Mica components are custom-built against provided drawings and specifications, which may vary from part to part. Fabrication is performed using foot or power presses and with the help of compound dies or tools. The Mica may also be drilled, hand-sheared, or lathe-turned. Products come in innumerable designs, each differing in pattern, size, thickness, and quality.

Types:

Small, cut parts of Mica are effectively used as backing plates on both the bottom and top sides of Mica Capacitors to provide mechanical rigidity and strength.

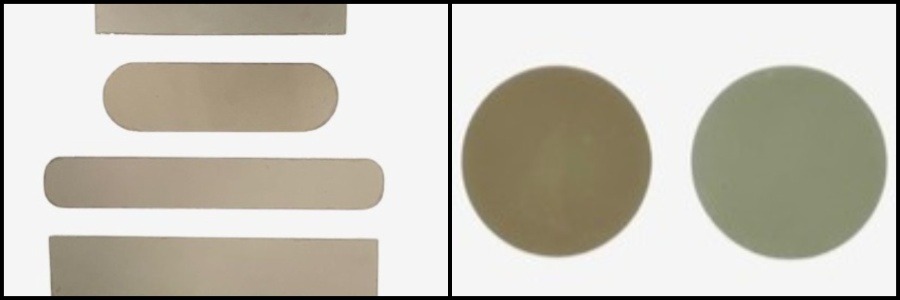

Superior-quality Mica Films of a specified shape and size are screen-printed with silver ink for application as an electrode in the manufacture of Mica Capacitors. Accuracy lies in clean-cut edges, flawless quality, and precise thickness.

Corrugated/Crimped Mica is made by passing natural sheet Mica through a specially designed rolling machine. It comprises vertically corrugated ribs and is mainly used in wrapping soldering iron electrodes. It plays an essential role in ensuring a dependable service life by eliminating physical contact between the copper bit and the resistance wire.

Mica Discs provide the best protection to circular viewport glasses and the perfect visibility to check the degree of combustion and the liquid level in high-pressure steam boilers. They are also used in breathing apparatuses, broadband waveplates for optical instruments, communication devices, fuses, Geiger counters, etc.

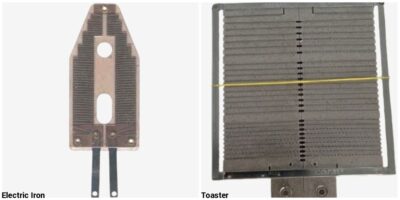

High-resistance electrical wire or nichrome is wound around natural Mica for providing quality insulation for application as a heating element in irons, kettles, rice cookers, toasters, and other electric heating appliances. It is available in many patterns and sizes, and comes in different and specified voltages and wattages.

Mica Insulators are precision-punched Mica parts crafted to specific dimensions and shapes. They serve as mounting washers and reliable insulators in diodes, ICs, heat sinks, power transistors, rectifiers, and other semiconductor devices. They insulate the semiconductor from the chassis, dissipate the heat away, and keep it cool.

Mica Shields are used with flat transparent sight glasses in columns of high-pressure steam boilers and liquid or water level gauges. They increase the service life of sight glasses in extreme steam pressures and high working temperatures, provide protection, and retain basic strength. They are a perfect, transparent medium to monitor the liquid level and steam pressure.

In the form of Mica Bridges or Spacers, Fabricated Mica is used in radio and television vacuum tubes. They help in maintaining the position of the tube elements, ensuring that they are distanced uniformly and insulated from one another.

Metal casting foundries pour their melts through a Mica Strainer Core to control the pour rate and eliminate impurities. A Mica Strainer Core with 22 to 148 holes acts both as a choker and strainer during pour.

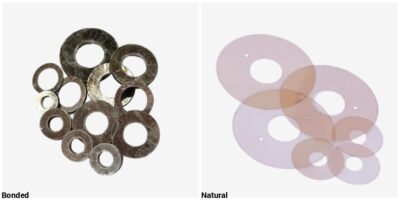

Natural Mica Washers are circular, punched, and stamped natural Mica parts with round openings in the center. They are suitable for electrical and electronic applications. On bonding into considerable lengths with epoxy, shellac, or silicone binders, they form a solid roll and are called Bonded Mica Washers. Maximum use is in grid resistors and railways.

High-quality and superior Mica is used in microscope slides for scientific research in laboratories. It has an even surface and a uniform layer, and is fully transparent and scratch-free.

Owing to flatness, high transparency, and thermal endurance, Mica is used as a viewing medium for fireplaces, furnaces, kerosene stoves, Petromax lamps, and wood stoves.

Wrapper Mica is produced through the die-cutting of Mica Thins and is rolled or wrapped into tube-form that is subsequently placed over soldering iron electrodes. It plays a vital role in ensuring a dependable service life by eliminating physical contact between the copper bit and the resistance wire.