Micanite or Built-Up Mica is crafted by layering overlapping Mica Splittings, which are laid-up by hand or mechanical processes and bonded with select resins (such as alkyd, epoxy, shellac, silicone, etc.) to obtain the characteristics for specific end-uses. It is then cured under high heat and pressure. A diverse range of composite binders are available according to temperature resistance and thermal insulation classes, namely “B” (130°C), “F” (155°C), and “H” (180°C), to meet different applications.

For some products, Micanite or Built-Up Mica is produced with numerous backing materials (such as glass fabric, Nomex paper, polyester film, etc.) to form a laminate which provides additional flexibility, mechanical strength, and tensile strength. Variations can be made in the production method to manufacture flexible or stiff and thick or thin Micanite products in the form of moulded articles, sheets, tapes, and tubes.

Micanite or Built-Up Mica is a vital insulating material employed in today’s electrical engineering industry. Without it, equipment and machinery would have to operate at greatly reduced efficiencies.

Types:

Commutator Cones/V-Rings are produced from moulding Micanite in different dimensions and shapes. Cones/V-Rings are initially cut out of Moulding Micanite Sheets. Then, they are moulded under heat and pressure to match individual specifications with the help of dies and moulds which are specially prepared for the process. They give excellent results but are labour-intensive and time-consuming during production. They are primarily used for insulation in commutators of high-voltage rotating machines.

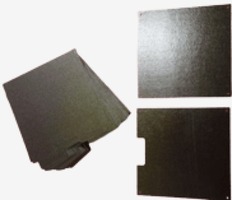

Commutator Micanite Sheets are produced from Mica Splittings incorporating low-level binders. They are completely cured, heat-pressed, and subsequently grinded on both sides. The flat, rigid, and smooth-surfaced sheets exhibit excellent mechanical strength, good voltage endurance, and high thermal stability. They have outstanding punching and shearing ability as well. They can be applied to commutator assembly works comfortably because of their stable compressibility and thickness accuracy. Commutator Micanite Sheets and their punched components are used as separators between the copper segments of commutators in electric motors, traction motors, turbo generators, etc.

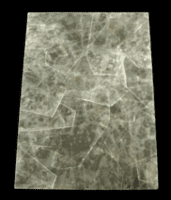

Flexible Micanite Sheets are made from Mica Splittings with heat-resistant bonding agents and resins. They possess excellent flexibility and permit winding or wrapping of the sheets at room temperature (without heating). They are reinforced with a protective backing on one or both sides to provide additional flexibility, dielectric strength, and mechanical strength. However, they can also be supplied without reinforcing a backing. Flexible Micanite Sheets are particularly suitable when cold wrapping of insulation is required. They are used in wrapped insulation of armature windings, electromagnetic coils, generators and transformers, ground insulation, motors, slot liners, etc.

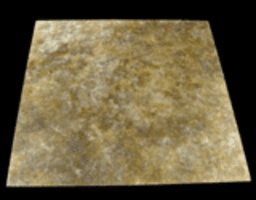

Heat-Resistant Micanite Sheets are made from Mica Splittings bonded with shellac or other resins. These plates are dense, hard, and rigid, and their percentage of binder content is kept relatively low. They possess excellent punching ability to any design and shape, and are used for heating elements in electrical appliances, furnace insulation, heat barriers, washers (for high-temperature applications), etc.

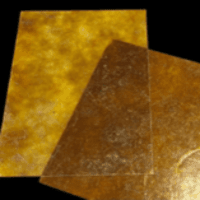

Moulding Micanite Sheet with natural shellac binder has been used in decorative lampshades for many years. Natural shellac varies from dark amber to orange in colour. The combination of Mica with the contrasting colour intensity and tone of binding resins creates a random and unique lighting effect. These sheets can be moulded into any desired shape when hot. The material becomes pliable and softens when heated between 100°C and 140°C for a couple of minutes. On cooling, they regain rigidity and retain the shape of moulded forms. The use of moulds to help shape the sheet into curvatures desired is recommended. Mica shade panels are assembled with ceiling, table, and wall lamps, and grand chandeliers in contemporary and vintage designs and fixtures.

Mica Folium is produced in continuous rolls comprising Mica Splittings bonded with various kinds of resins. On one side, it is reinforced with kraft paper or other backing material based on the amount of dielectric strength, flexibility, and mechanical strength demanded by the applications. Mica Folium is mainly used in casings, cylinders, and forming tubes. It is suitable for the insulation of bus bars and for layered insulation in both high and low voltage installations.

Micanite Bushes/Tubes are made from Mica Folium sheets in different dimensions. The sheet is heated and wound at elevated temperatures to form rigid tubes. The desired wall thickness, along with the required inside and outside diameters, is acquired. They find application in brush holder assemblies, commutator sleeves, electrical resistances in industrial equipment, switch gears, etc.

Micanite Tapes are manufactured in continuous rolls comprising Mica Splittings bonded with various resin binders that thermally adapt to insulation classes. They involve a combination of several backing or supporting materials depending upon the requirements and specifications. Reinforcing materials provide resistance against abrasion, sufficient tensile strength, and uniformity. For a lot of applications, Micanite Tapes have been replaced and superseded by Mica Paper Tapes. They are essentially used in coils of generators and motors and transformers, high-voltage cables, insulating armature coils, windings of electrical machines, etc.

Moulding Micanite Sheets are made from Mica Splittings bonded with modified shellac or other resins. They are rigid at room temperature and soften when heated between 100°C and 140°C. They comprise a relatively high level of binder content for having the necessary flexibility to easily mould into any desired shape upon heating. On cooling, they regain rigidity and retain the shape of moulded forms. Moulding Micanite Sheets are chiefly used for making angles, bushings, channels, commutator V-rings and cones, decorative lamp shades, endcaps, etc.